Hydrostatic testing is a process where components, such as piping or pressurized containers are tested for strength and leaks by filling the equipment with pressurized liquid.

All Florida Fire Equipment is one of the largest DOT hydrostatic testing facilities in the Tampa area. We pride ourselves on our quick turnaround time and our attention to detail. We have the ability to hydrostatic test almost all cylinders with a DOT number including but not limited to:

• Scuba Tanks

• Paint Ball Tanks

• Medical Oxygen Tanks

• Chlorine Tanks

• Beverage Tanks

• Keg orator Tank

• Nitrogen Tanks

• Co2 Beverage Tanks

• SCBA Cylinders

• Propane Tanks

• Low-Pressure Aluminum Cylinders

• Compressed Gas Cylinders

• High-Pressure Aluminum compressed gas cylinders

• Fiber-reinforced high-pressure cylinders

• Marioff High Fog Cylinders

• Co2 Fire Extinguishers

Hydrostatic Testing (Requalification) – The Process

A brief description of the requalification process follows. The cylinder has its valve removed and all external and internal surfaces made visible to the DOT (Department of Transportation) qualified hydrostatic tester. The cylinder is externally and internally visually inspected according to required DOT specifications. If it passes, the hydrostatic test is performed.

To hydrostatically test the cylinder, it is placed inside of a water jacket (containing water) which is sealed with hydraulic clamps. The cylinder is filled with water. The cylinder is then pressurized with even more water via a high-pressure pump. The cylinder expands a little and displaces water in the water jacket. The amount of water displaced in the water jacket is measured by a precision method. This amount of water displaced signifies how much the cylinder expanded under pressure. When the water pressure returns to normal, the amount of expansion that still exists (the water not taken back into the water jacket) is called the permanent expansion. This information is recorded and compared to DOT requirements to determine if the two expansions of the cylinder adhere to DOT regulations.

If the cylinder passes the internal and external inspection and retest, the retester marks the all-metal cylinder by stamping into the metal or labels a composite cylinder with a label sealed in resin. The information marked or labeled includes the RIN identification and the retest date. A record is then made of the requalification with the information mandated by the DOT.

The retester is required to stamp out cylinder DOT markings with X’s or with the word “Condemned” if the cylinder does not pass the hydrostatic testing process. Cylinders that are fully wrapped with composite materials that do not pass requalification are labeled condemned. The cylinder should be rendered unable to hold pressure with the permission of the cylinder owner. It is recommended that all cylinder owners permit the hydrostatic testing facility to render condemned cylinders unable to hold pressure by drilling through the cylinder or terminating valve threads. A record is made of condemned cylinders, according to DOT standards.

Other Cylinder Services We Offer:

• Bead Blasts

• Scuba Visual Tank Visual Inspections

• Cylinder Tumbling

• Fiber Wrapped Tank Repair

• Eddy-Current Testing (electromagnetic testing on cylinder treads)

• Valve Removal

• O2 Cleaning

• Disposal

All Florida Fire Equipment is a fully licensed hydro testing facility.

If you are anywhere in the Tampa, St. Petersburg, Clearwater, Lakeland, Largo, Sarasota, or Bradenton areas, we are just a phone call or email away. Call us at 727-525-5950, or email us at service@allfloridafire.com. If you prefer, fill out our easy Contact Us form, and we’ll reach out to you.

How often do I need to have my tanks hydro tested?

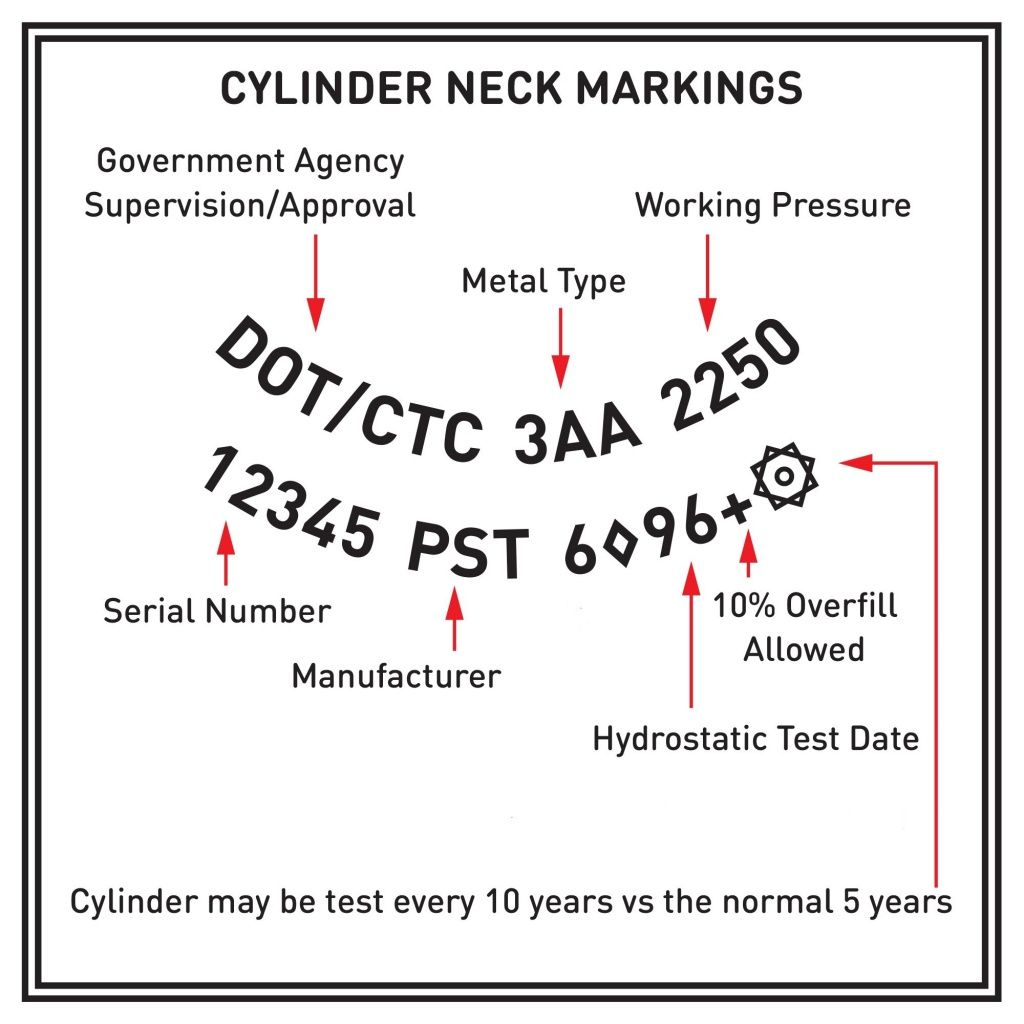

You can check the testing requirements of your equipment by referring to the DOT sticker on your cylinder. All the information the tester needs is there including the serial number, manufacturer, and manufacture date.

If you are uncertain about the testing requirements of your equipment, you can find more information on the DOT website, or just contact All Florida Fire Equipment and we can do the research for you.

These common gas cylinders have the following testing requirements:

DOT-3AL gas cylinders must be tested every 5 years and have an unlimited life.

DOT-3HT gas cylinders must be tested every 3 years and have a 24-year life.

SP-Cylinders Special Permit

DOT-3AA gas cylinders must be tested every 5 years and have an unlimited life. (Unless

stamped with a star (*) in which case the cylinder meets certain specifications and can have a 10-year hydrostatic test life)

In the U.S. and Canada, organizations such as ASTM, and ASME specify the guidelines for the different types of pressure vessels.

Cylinder Markings